- HOME

- MARKETS

- Quality of Life

- Sporting Goods

- Golf

Golf

Carbon fiber shafts are longer but light, so they can produce high head speeds and longer carries.

A golf club that performs well must be able to drive the ball far, and in the intended direction. To improve the drive, the shaft needs to be lighter since to increase the head speed it is important to increase the initial speed of the ball by making the club lighter. In doing so, it is important to keep the club strong enough that it will not break. With TORAYCA™ we have achieved straight materials that offer good bending strength through developing standard-elasticity high-strength yarns with an elastic modulus of 24 tf/mm2 and moderate-elasticity high-strength yarns with an elastic modulus of 30 tf/mm2. In addition, we have recently developed the new high-strength and high-modulus carbon fiber TORAYCA™ T1100G, which has the previously difficult-to-achieve properties of being both high strength and high modulus. We have also developed new high-performance prepreg using our NANOALLOY™ technology, contributing to reducing weight as much as possible.

In terms of directional performance, it is important to improve the shaft's resistance to twisting (reducing torque) so that the ball direction is not negatively affected by the shaft twisting, which causes the shaft's center axis and head to be out of line when striking the ball. As torsional rigidity is highest when the layering angle is at ± 45°, a ± 45° layering angle is incorporated as a way of reducing twisting (torque), a high-elasticity yarn with an elastic modulus of 40 tf/mm2 is used as a bias material against twisting as standard. Now, TORAYCA™ high-elasticity yarn of 46 tf/mm2 and above may also be used in some cases.

Shafts formed through sheet winding using prepreg basically consist of an internal layer angled at ± 45° (called "angle layer" or "bias layer"), a lengthwise layer material angled at 0° (called "straight material") and a material to reinforce and thicken the hosel. A shaft's characteristic flex, torque, weight, and kickpoint are determined by the combination of these layers. These combinations of layer angles and thicknesses using carbon fibers have made it possible to optimize designs in ways that were not possible with conventional metals, making it a material that can achieve optimal performance at the lightest weight. Toray also leverages its expertise to make recommendations to customers on optimizing design through our vast materials database and through CAE analysis.

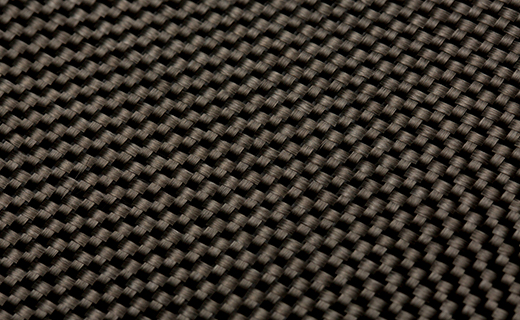

Nowadays, it has become common to reduce the weight of the golf head crown using CFRP in order to provide improved design freedom in terms of the weight of the golf head. TORAYCA™ has a product lineup of cloth (textiles) and fast-curing resins optimized for press curing for use in a wide range of applications such as this.

The combination of flex, torque, weight, kickpoint, and weight distribution of the golf head can be designed to suit the physical needs of each golfer. TORAYCA™'s industry-leading lineup is used in a wide array of golf clubs, from average golfers to top pros, and from hard-hitters to female or senior citizen golfers. TORAYCA™ will undoubtedly continue to play an important role in the evolution of golf.

Why TORAY Materials?

Toray has a broad range of composite material solutions to suit a diverse range of requirements within the golf market.

Lightweight

With Toray's high-strength and high-modulus carbon fiber TORAYCA™ T1100G and high-performance prepreg using new NANOALLOY™ technology, Toray's innovative technologies push the limits of weight reduction.

Cosmetic Finish

Toray recommends high-quality textiles to give golf heads a beautiful look.

Optimal Design

Toray is a pioneer in carbon fiber golf shafts, with years of expertise, a rich materials database, and CAE analysis technology. Toray makes recommendations for designs that are resistant to twisting and breaking, and optimized to suit each golfer's physical needs.

Diverse Resin Line-Up

Not only does the resin matrix (epoxy resin) used in TORAYCA™ prepreg harness the full performance of carbon fibers, Toray also has a varied product line-up that includes the resin applying nano-level material control technology called NANOALLOY™ with improved dynamic properties, quick-curing resin that improves press-curing production efficiency, high-heat-resistance resin, vibration-absorbing resin, and impact-resistant resin.

NANOALLOY™ technology is an innovative microstructure control technology. We own the basic patent, core process patents and utility patents.

Click here for more details on the third-generation carbon fibers — TORAYCA™ T1100G and TORAYCA™ M40X — which achieve both strength and stiffness (elastic modulus) at a higher level.

Toray Composite Materials for Golf

Related links of Toray group company (External Pages)

| Company Name | Country | Links | |

|---|---|---|---|

| Toray Composite Materials America | US | Prepreg: Sports & Industrial |