- HOME

- PRODUCTS

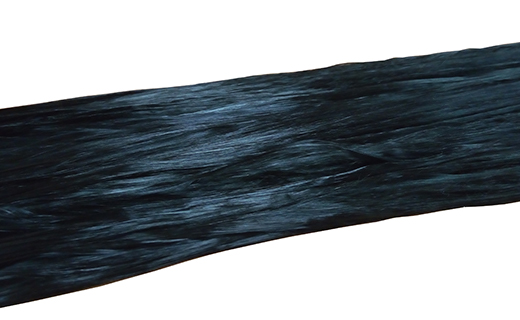

- Oxidized Fiber

Oxidized Fiber

We have produced oxidized PAN fiber ZOLTEK™ OX for over 25 years. This level of experience, innovation and expertise has allowed us to fine-tune its process and become the largest oxidized-PAN-fiber producer in the world.

ZOLTEK™ OX is available in various formats, including continuous tow, staple fiber, felts, fabrics and spun yarns.

End uses include aircraft brake preforms, transportation heat and flame blocking layers, thermal, acoustic and vibration insulation liners, flame-resistant apparel and intumescent meshes. It is also used as a raw material for carbonized and graphitized yarns, fabrics and felts.

Lineup

Why TORAY Materials?

Flame Resistant

ZOLTEK™ OX is inherently flame resistant, making it an effective heat-blocking and fire barrier material. It outperforms all other organic flame resistant fibers in terms of limiting oxygen index and does so at a very competitive price.

Versatility

One of the largest benefits of ZOLTEK™ OX products is their versatility. ZOLTEK™ OX is available for all forms of textile processing including: needle punching, stitch-bonding, hydroentangling, thermal bonding, chemical bonding, air-laying, wet-laying, ring spinning, stretch-breaking, weaving, knitting and braiding.

Textile Nature

ZOLTEK™ OX textile products retain their appearance, have a soft hand and retain their textile characteristics, even after open flame exposure. Besides not burning, melting or dripping, ZOLTEK™ OX fibers will not shrink and they self-extinguish, when exposed to flame.

Chemicals Resistance, Friction Resistance

ZOLTEK™ OX is often used for braking materials that withstand extreme conditions that demand resistance to harsh temperature, chemical, and friction environments.