- HOME

- ABOUT US

- Sustainability

- Recycling

Recycling

Thermoplastic Recycling using Cetex®︎

Innovations in Thermoplastic Recycling Technologies Using

Cetex® TC1100 C/PPS Reinforced Thermoplastic Laminates

TPAC TPC-Cycle Project

The TPC-Cycle project targets production scrap by developing a recycling route for high-end and high volume markets, The objective is to retain the high mechanical properties of thermoplastic composites and reduce the overall environmental impact at affordable cost. This process has been used to produce the world's first flying part made using recycled thermoplastic composite materials.

Images courtesy of TPAC/Saxion

Trimmings

Surplus material derived during production of thermoplastic components

Shredded Flakes

The trimmings are shredded to large flakes to retain long fibers. The shredding technology covers the influence of scrap geometry and setup variables to obtain uniform and desired flake sizes.

Molten and Mixed Dough

Material is first heated upon melting and mixed, while preventing fiber breakage. A molten dough is subsequently extruded.

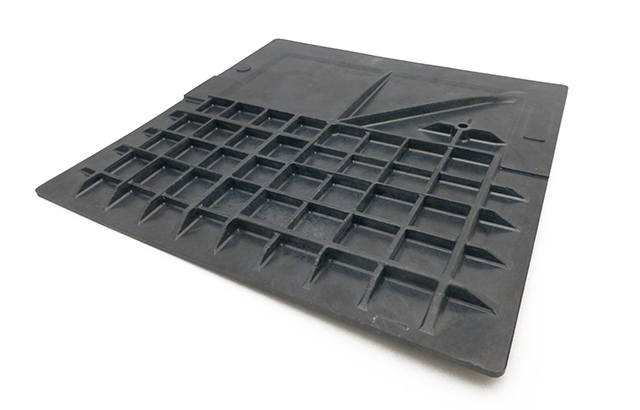

Molded Part

The mixed dough is compressed and cooled, using compression molding processing methodology.

Toray R+D Development

Toray Advanced Composites' Research and Development team have developed a new look for the recycling of advanced thermoplastic composites through introduction of a recycled "flow layer" made using recyclate derived from the production of thermoplastic composite components.

- Improved performance-to-weight ratio

- Balanced use of recycled materials

- Utilize existing processing methods

- Near 100% buy-to-fly ratio

- Traceability of recycled materials

Trimmings

Surplus material derived during production of thermoplastic components

Recyclate

Thermoplastic trimmings are grinded to produce recyclate

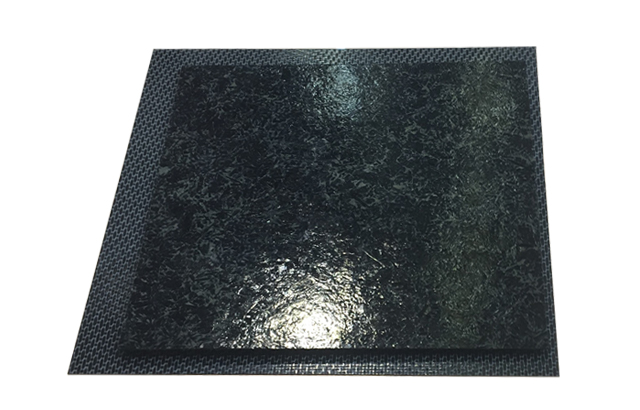

Flow Layer and Woven Reinforced Thermoplastic Laminate

The flow layer consists of highfiber volume fraction recyclate, which processes as a Bulk Molding Compound and can be positioned on a conventional Reinforced Thermoplastic Laminate or added locally prior to processing.

Finished Part

The stamp molding process itself is conventional, i.e., the laminate can be stamp formed/press molded to shape in short-5-minute thermoforming cycles.

Need more information about Cetex®? Please contact us here.

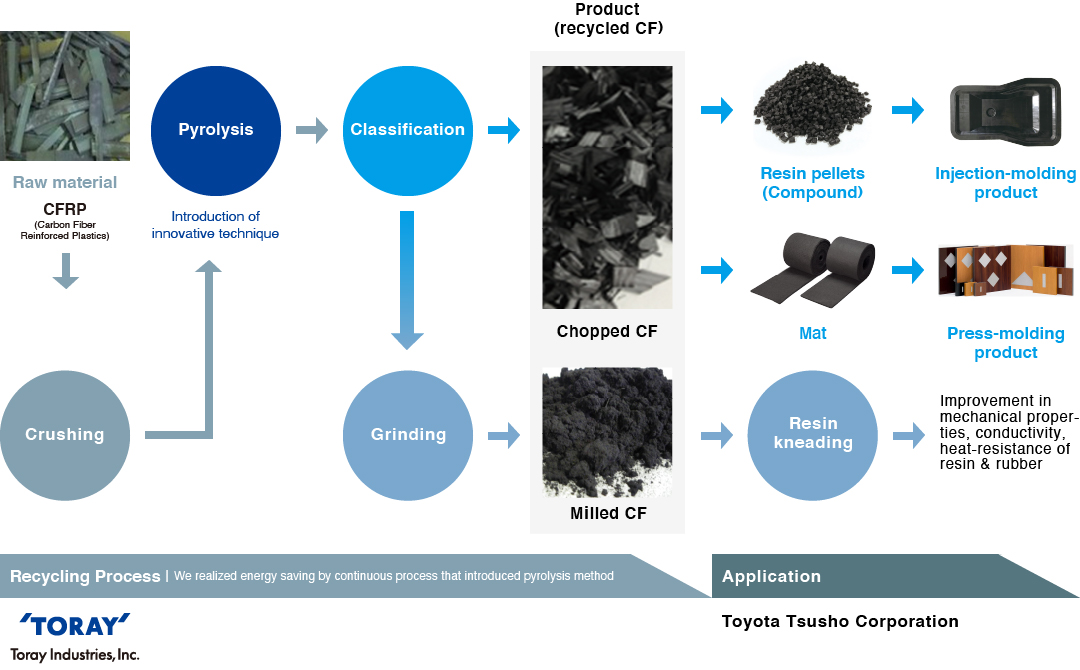

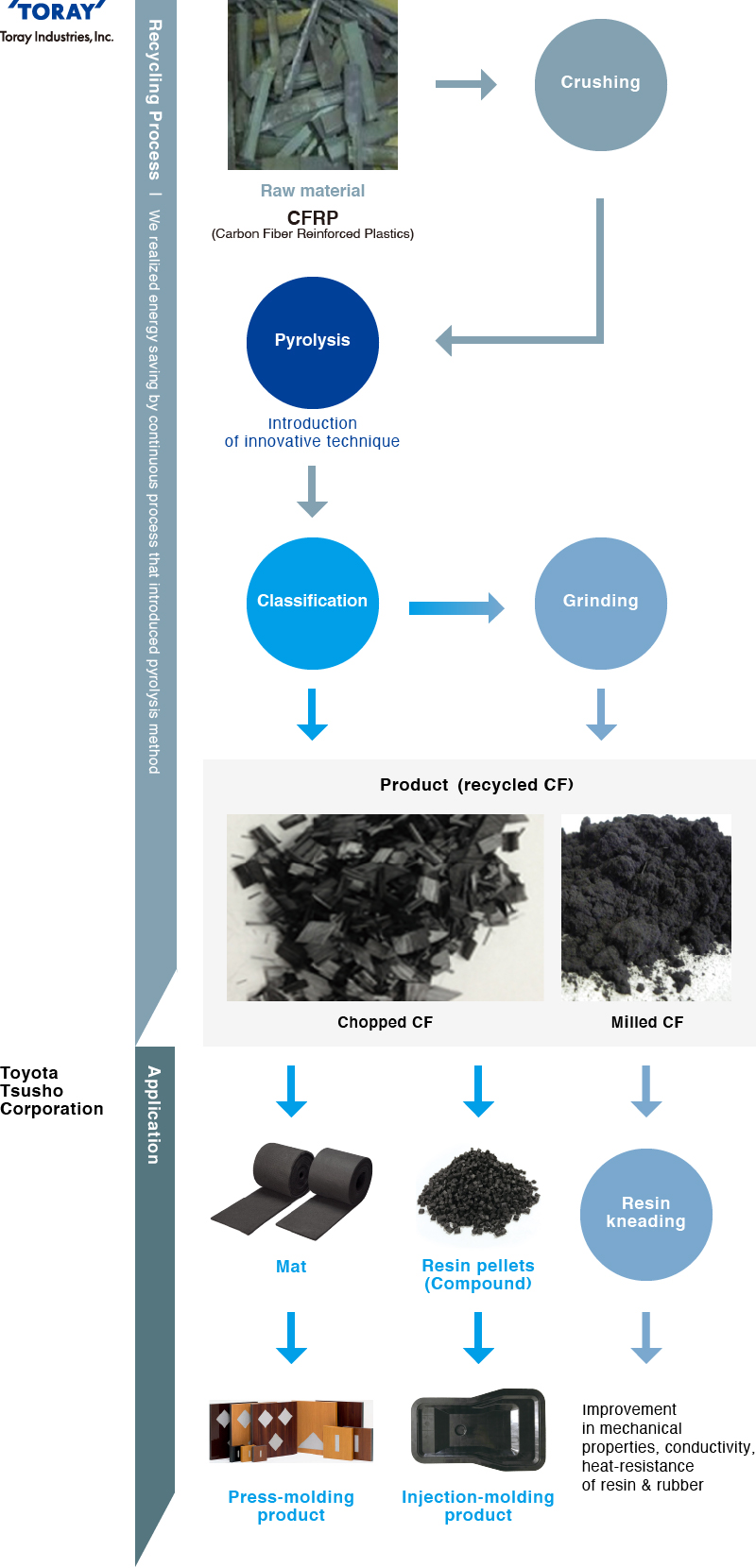

Thermoset Recycling Technologies

Toray Industries, Inc. and Toyota Tsusho Corporation jointly developed the innovative energy-saving pyrolysis method for CFRP recycling and are promoting end use development.