- HOME

- ABOUT US

- Sustainability

- Life Cycle Assessment

Life Cycle Assessment

Carbon fiber is an environmentally friendly material.

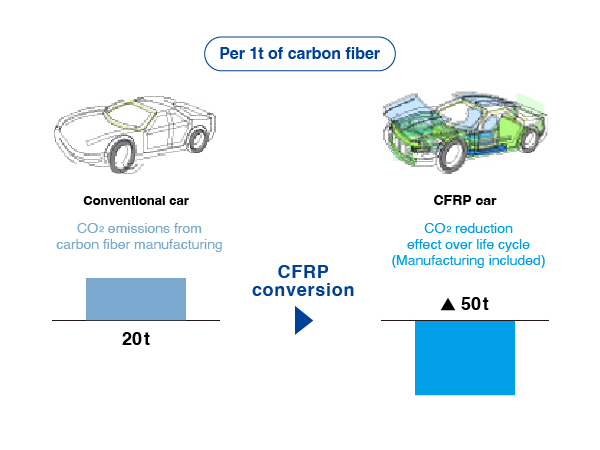

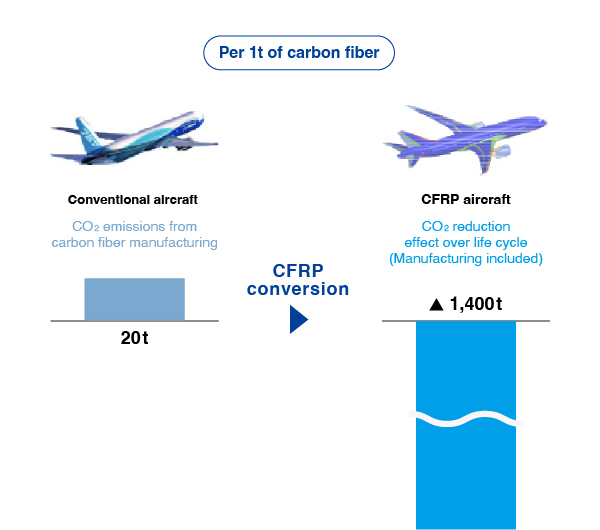

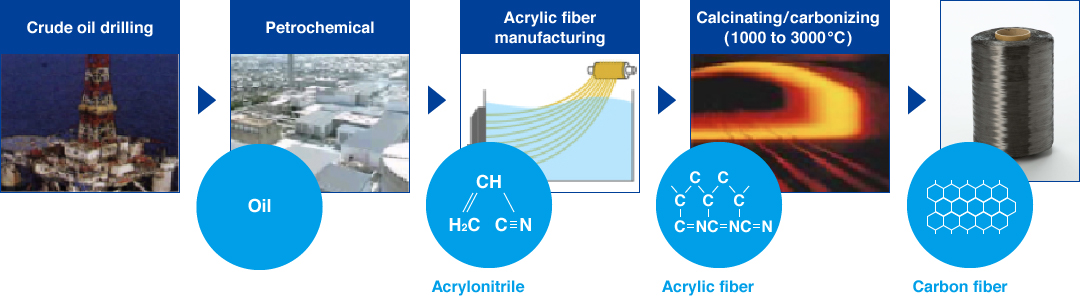

Carbon fiber is manufactured by refining oil to obtain acrylonitrile and then spinning this acrylonitrile and baking the spun yarn. Due to the high baking temperature of 1000℃ or more, 20 tons of CO2 are emitted to manufacture 1 ton of carbon fiber.

Carbon fiber offers excellent specific strength and specific modulus of elasticity, and its market is expected to grow significantly.

Carbon fiber contributes significantly to curbing of global warming.

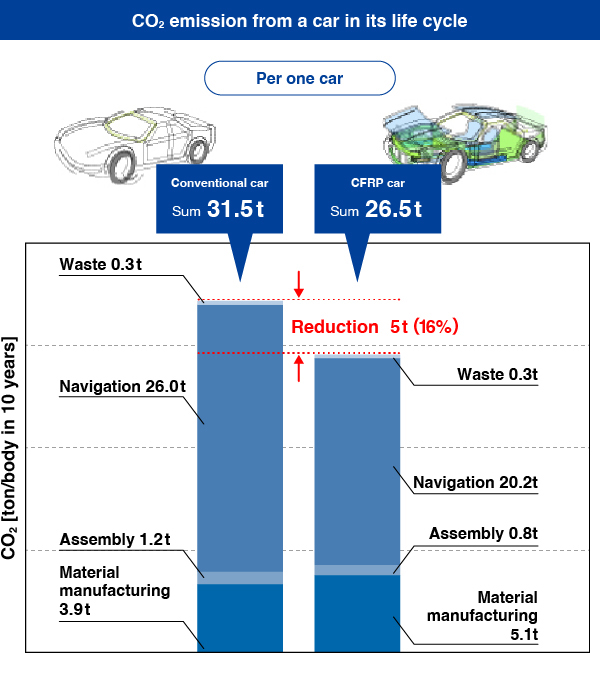

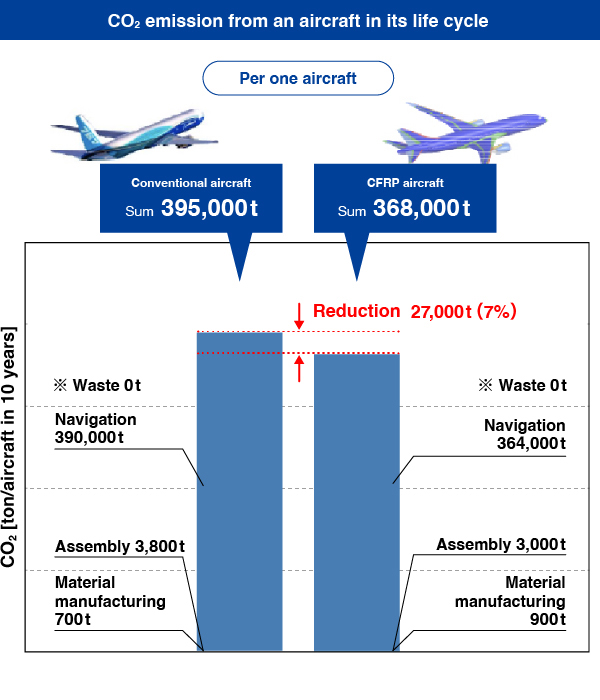

The environmental impact of carbon fiber was evaluated using the LCA (Life Cycle Assessment) method over is life cycle from digging of material to use and scrapping of carbon fiber product. The result is as follows.

When 17% of a car body structure is made of CFRP (carbon fiber reinforced plastic), 5 tons of CO2 per one car will be reduced over a life cycle of 10 years; when 50% of an aircraft fuselage structure is made of CFRP, 27000 tons of CO2 per one aircraft will be reduced under the same condition (cited from model by The Japan Carbon Fiber Manufacturers Association).

When 17 % of a car body structure is made 30% lighter using CFPR, 50 tons of CO2 will be reduced per 1 ton of carbon fiber over a life cycle of 10 years; when 50% of an aircraft fuselage structure is made 20% lighter using CFRP, 1400 tons of CO2 will be reduced under the same condition.